The Issue of Rapid Industrial Growth and Groundwater Depletion

With rapid industrialisation, Hebei Province in China has witnessed continuous growth in industrial water consumption. As a result, the region is facing serious water shortages and contamination from heavy industrial water use and wastewater discharge.

With insufficient surface water available, groundwater has been exploited excessively to support water demands. This has led to a series of ecological problems, including the depletion of aquifers, land subsidence, saltwater intrusion, and reduced streamflow.

Water as an Essential Industrial Resource

Water is an essential resource for the industrial sector and developing countries are facing relatively higher water risks as economic growth correlates with increasing water usage. However, there is no viable substitute for water in most industrial processes.

Sustainability Pressures

The compounding issues of scarcity, reduced quality and inefficient utilisation of water restrict sustainable development and long-term economic growth.

A stable, sustainable water supply has become a key focus for stakeholders in industry, including shareholders, lenders, regulators, governments, and customers. Therefore industries (particularly manufacturing) are facing increased pressure to meet sustainability goals.

ESG goals have attracted increasingly extensive attention. As a response, governments and corporates commit to resource conservation and net-zero transition, aligning their development trajectory with recognised environmental principles.

Water is an essential resource for the industrial sector and developing countries are facing relatively higher water risks as economic growth correlates with increasing water usage.

In 2019, the average burial depth of shallow groundwater in Hebei Province increased from 9.3m in 1986 to 18.2m (1).

Closed Loop Water Recycling as a Solution

Because the cost of responding to water risk tends to be much lower than the financial impact of inaction, it makes financial sense for industrial producers to treat and reuse their water.

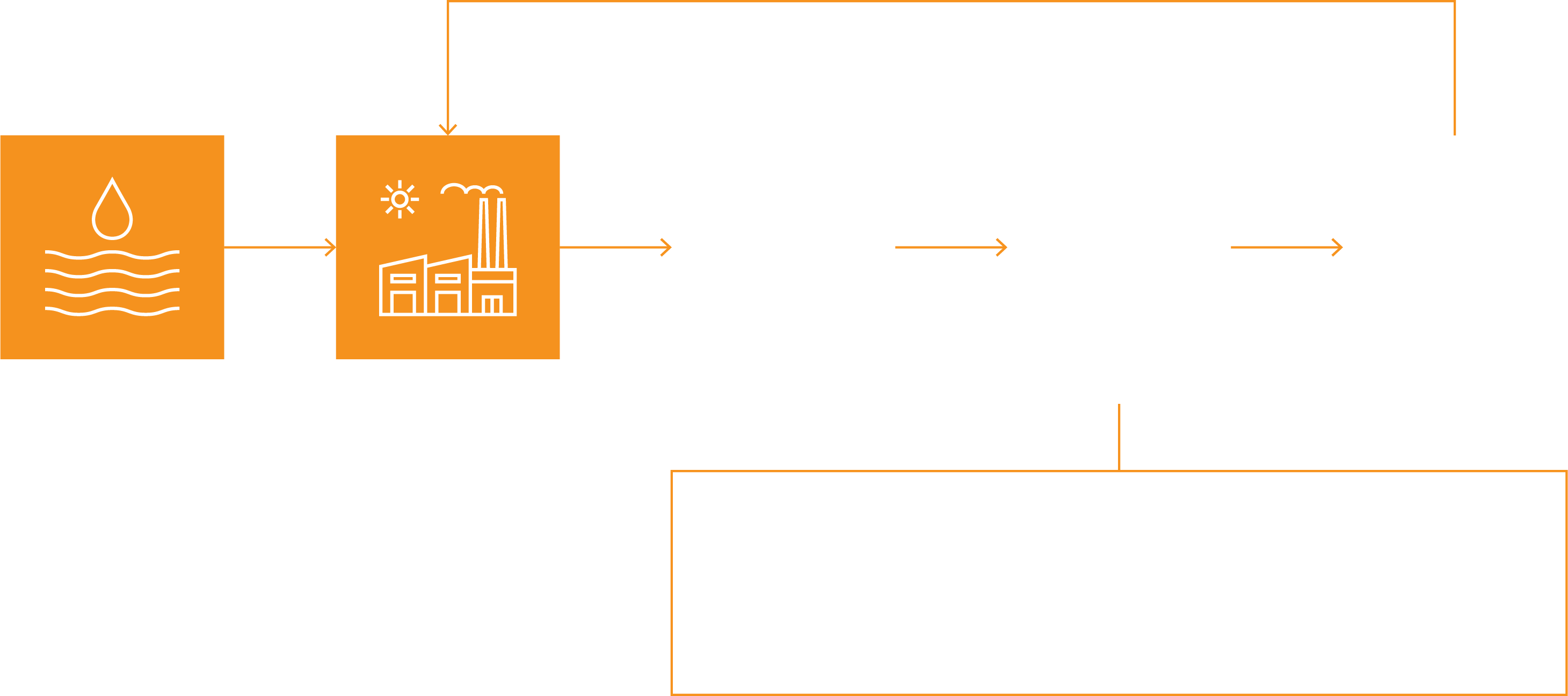

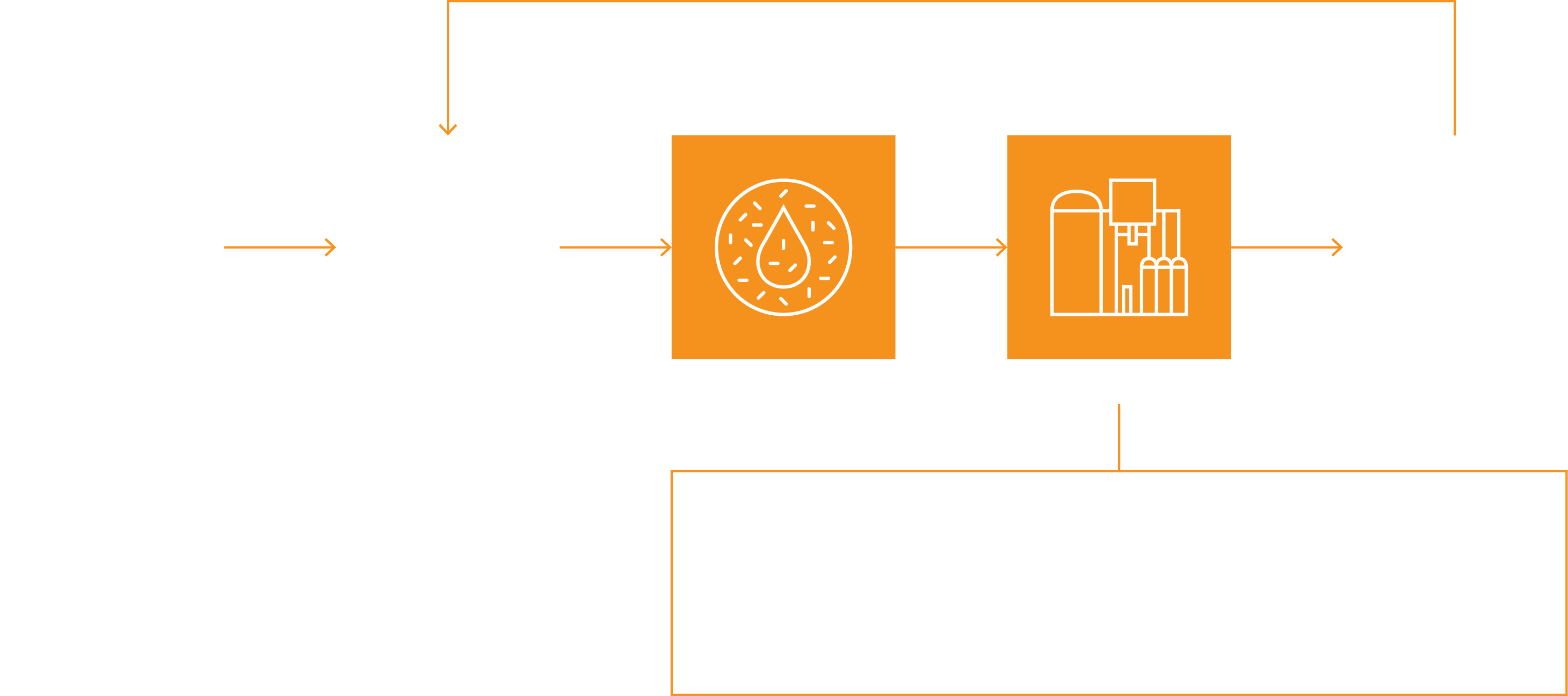

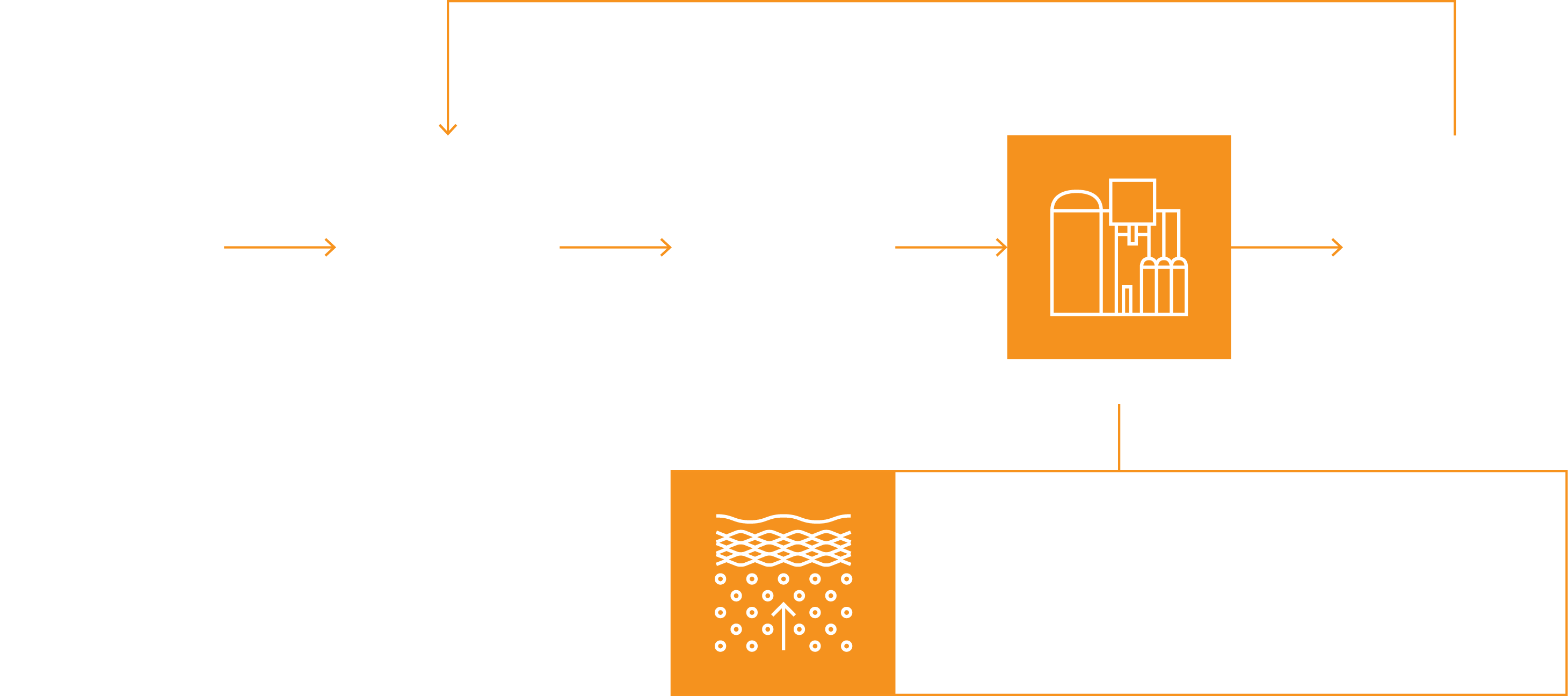

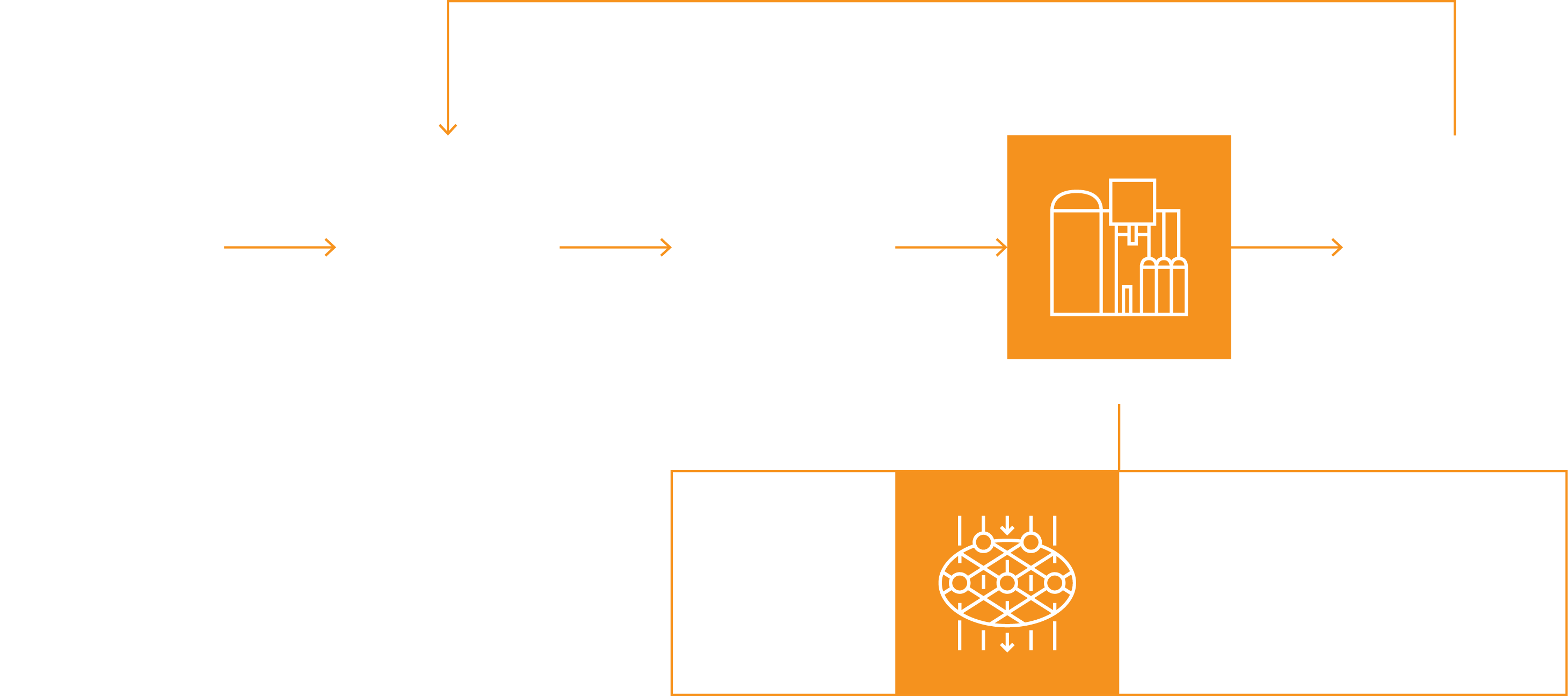

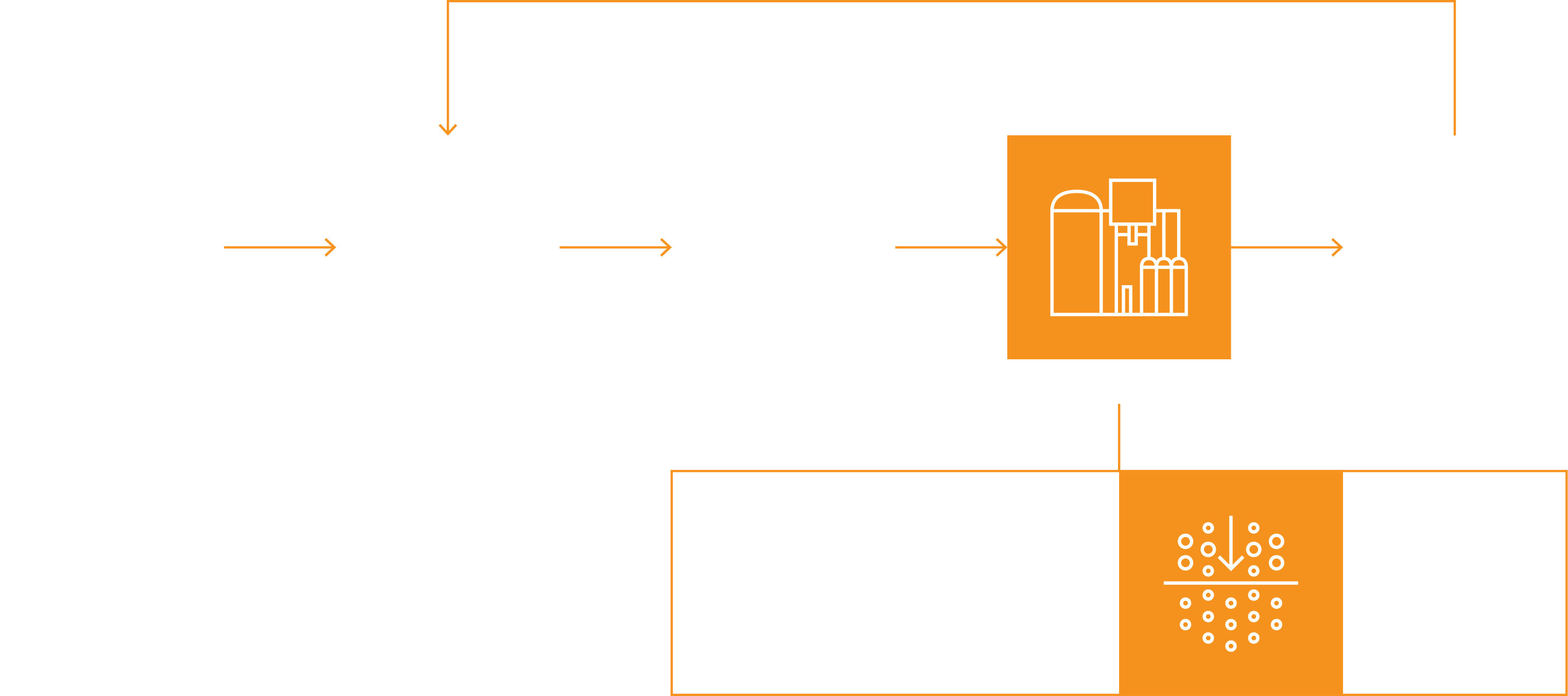

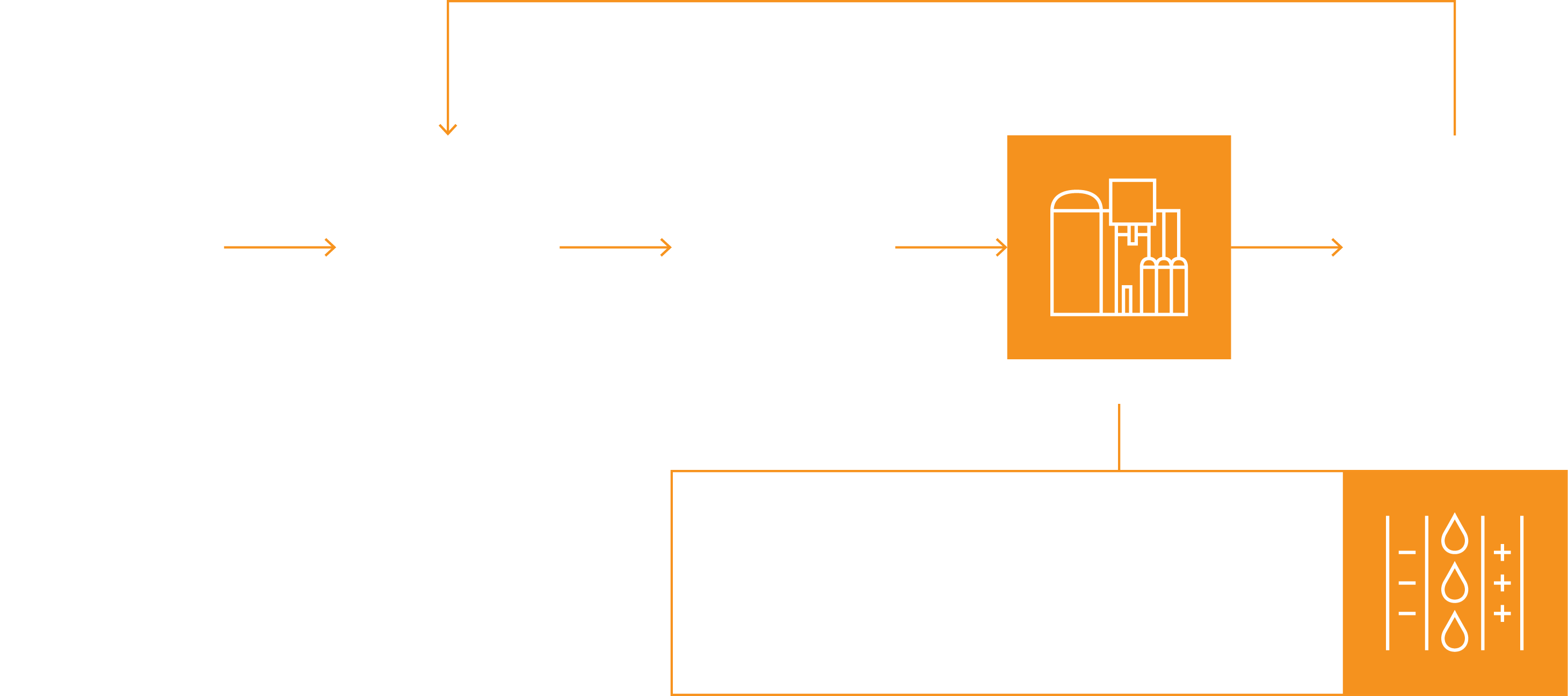

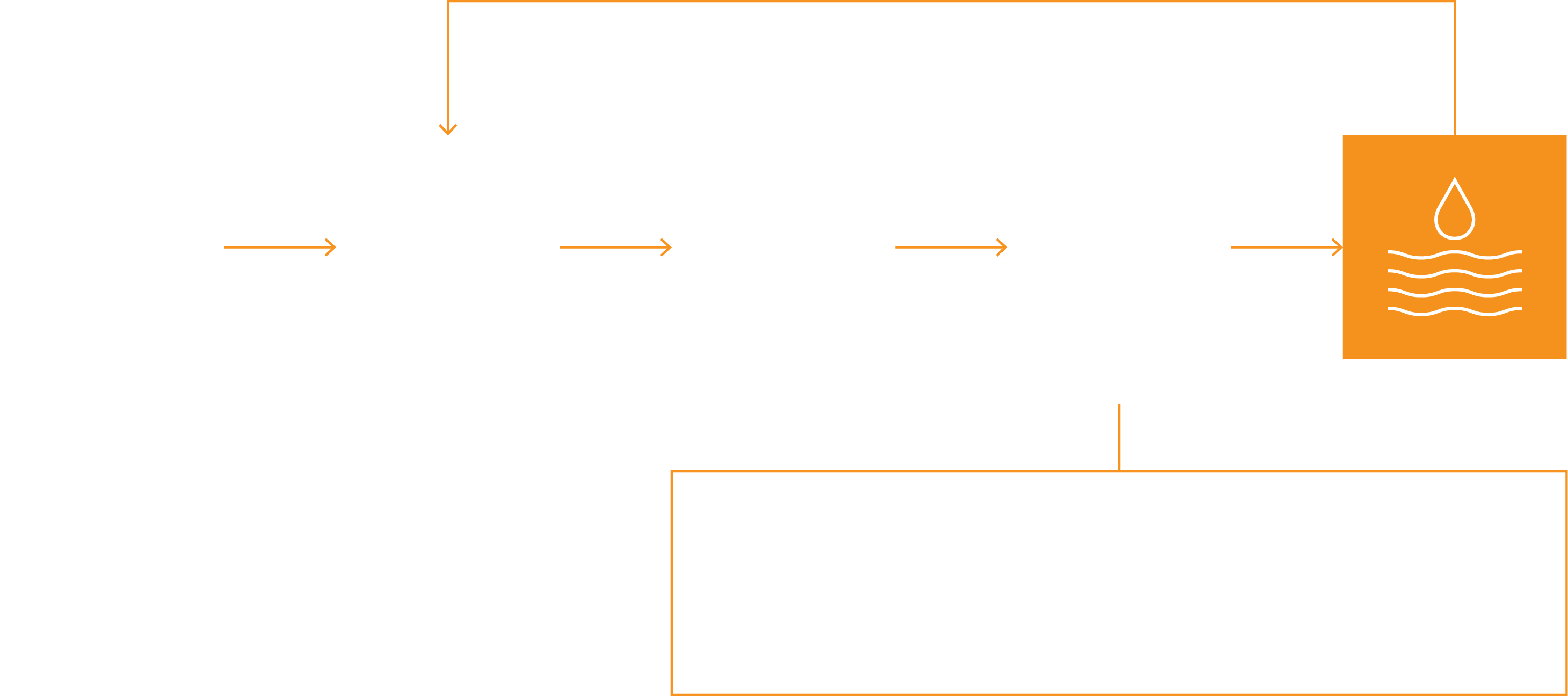

A closed-loop water recycling system enables industrial producers to reclaim, treat and reuse the water they use in their industrial processes.

Closed Loop Water Recycling

Project SY

Asset: Closed loop water recycling system

Industry: Chemical fibre manufacturing

Location: Hebei Province, China

Production: >40,000m3/day of recycled water

Project SY (a Resonance investment) provides a closed loop wastewater recycling system for an industrial client operating in the chemical fibre manufacturing industry. The system supplies over 40,000m³/day of recycled water for reuse in the chemical fibre production.

The feedwater is treated wastewater sourced from a local wastewater treatment plant co-located inside the industrial park (secured by a long-term wastewater supply contract with the local government).

The water reuse plant uses established technologies and standardised processes, including biological filters, ultrafiltration, reverse osmosis, and ion exchange.

Project revenue is driven by reuse water sales under a long-term reuse water purchase agreement with the client.

Project SY has provided a consolidated solution to industrial water resource management, promoting wastewater valorisation and circular economy. It has established a demonstrative pilot of wastewater recycling and reuse in the industrial park, and is a reference for larger-scale applications in the future.

(1), (2), (3) Hebei Water Resources Bulletin, 2022.

(4) Driving factors of industrial water use change based on carbon emission and sectoral perspectives in Hebei Province, China, 2023.